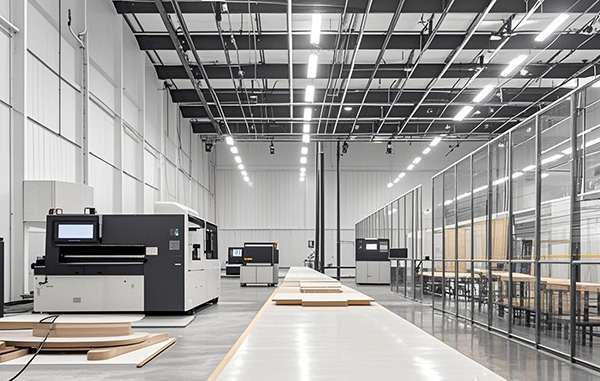

Capable Manufacturing of Quality Furniture

Filodio focuses on the details to produce quality furniture. Manufacturing large sets of furniture annually at peak quality is possible through our precision machinery, efficient team, and superior materials .

2

Factories

50000㎡

Production Area

100000sets

Annual Output

1000sets

Annual Output of Upholstered Beds

Elite Craftsmanship at Furniture's Advanced Facilities